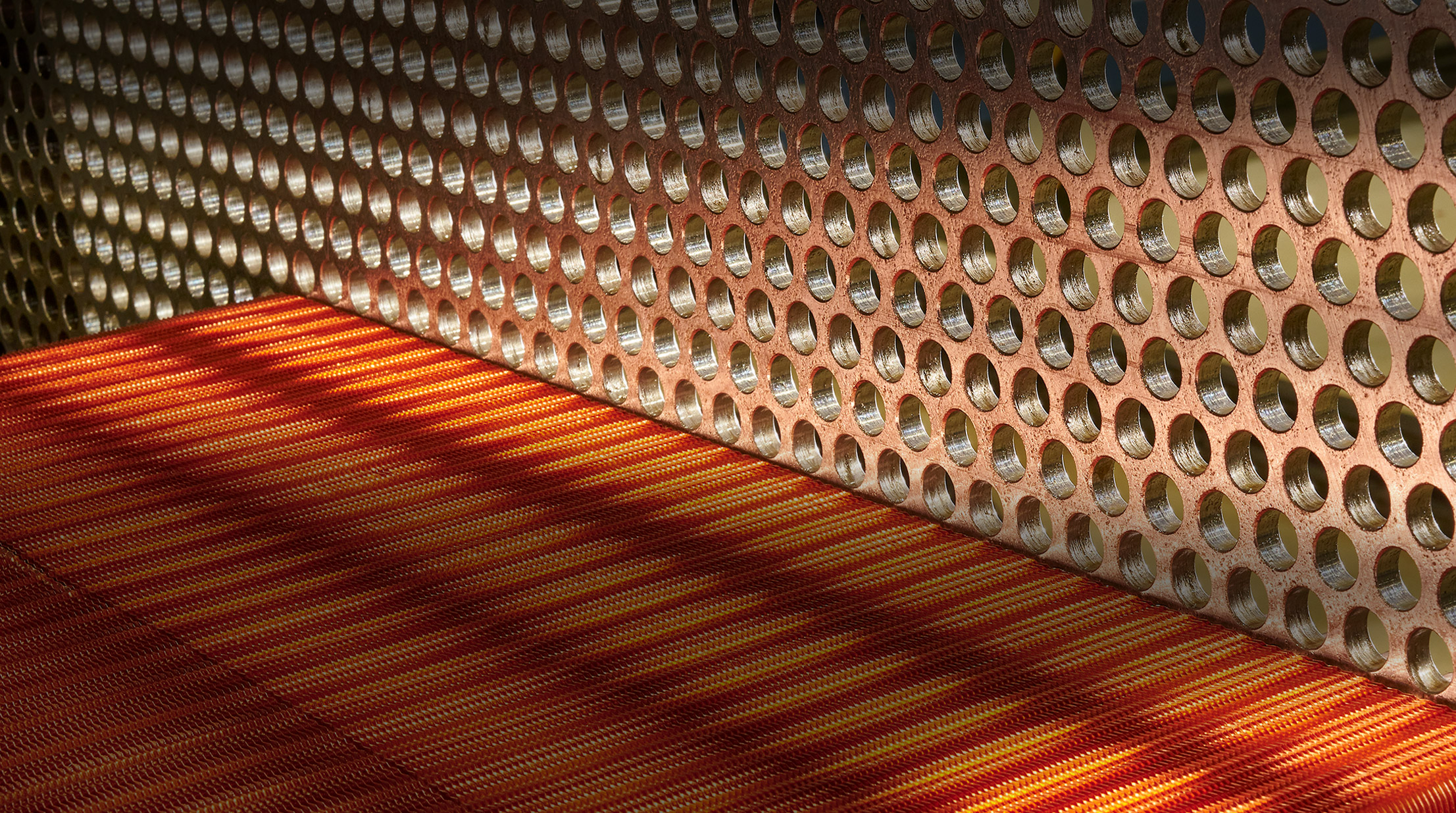

Vestas produces its charge air coolers using a range of fin geometries.

There are details here of our Ultra Compact, Compact, Standard & Premium Tin Coated geometries.

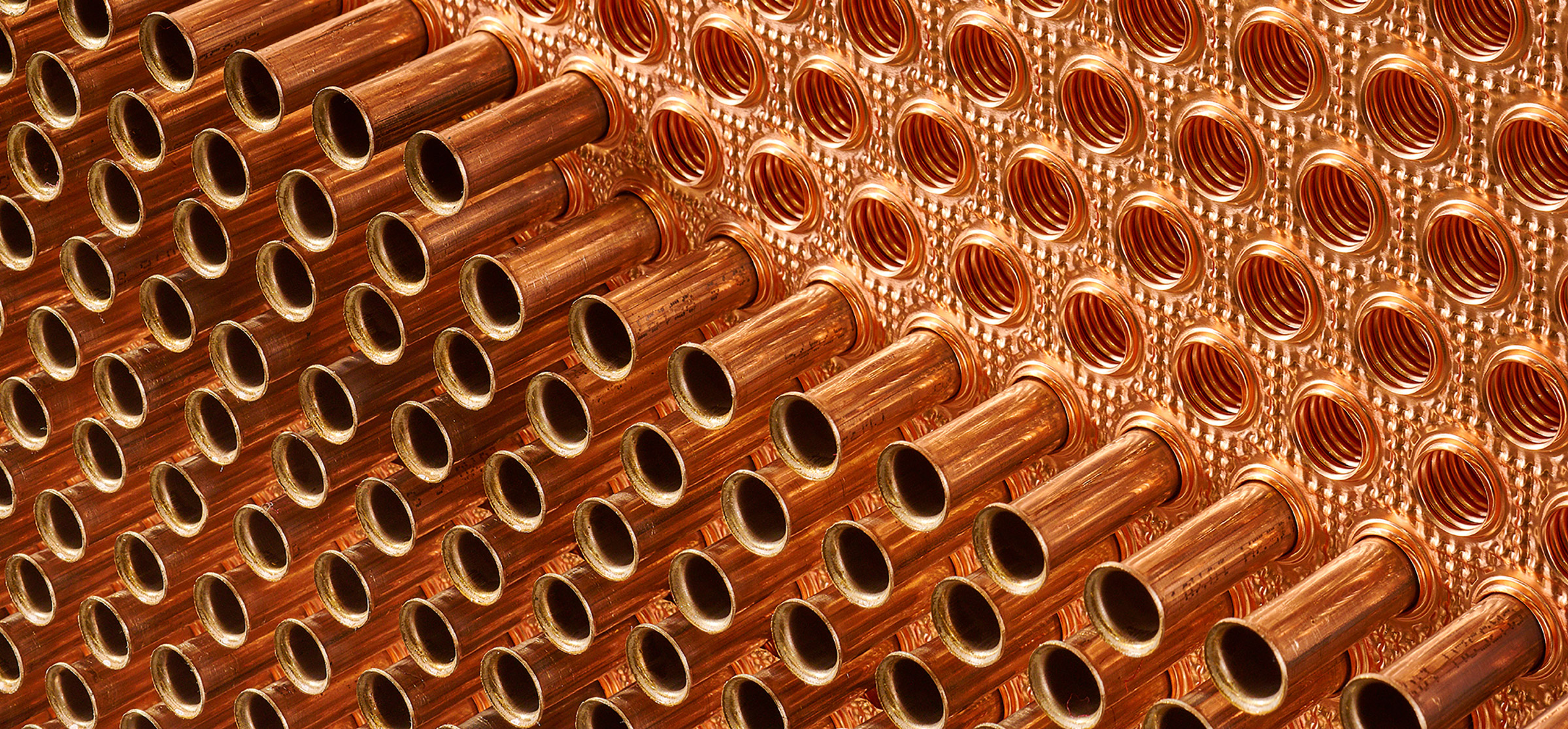

One-piece construction – peace of mind.Any air cooler over a few hundred millimeters in length needs a proper support mechanism. The science behind the

calculations that determine its requirement and position is complex, but the method is simple.In the same way as the tubes are roller expended into tube plates at either end of the charge air cooler, they are also

mechanically bonded to support plates, strategically placed along the length of the air cooler.The plates are then attached to the side panels. The precise position and method of attachment differs depending

on the environment and is itself, the subject of complex design considerations.

In combination with MonoBloc – Vestas coolers are the most robust available.

MonoBlock charge air coolers

Vestas produces its charge air coolers using a range of fin geometries.

There are details here of our Ultra Compact, Compact, Standard & Premium Tin Coated geometries. Fewer parts = Fewer problems.Limitations on the maximum size a fin can be produced traditionally led to a restriction of the width of the fin.

Thus, coolers in the past are built with multiple smaller fin “elements”.

Vestas has extended its maximum fin width to 77 tubes wide, big enough for almost all size of coolers – we call it a “MonoBlock” element.

A MonoBlock combined with a full integral support plate means there is effectively a one-piece element.

Fewer components means a more robust air cooler. Perfect where there is vibration.